The aim of the project is to advance digitization in construction, architecture and design, thereby increasing productivity using new resource-saving manufacturing technologies, such as the so-called 3D printing process. One focus is on shaping cement materials without the currently still obligatory formwork by means of additive manufacturing technology in a digital process chain individually and according to requirements and opening up new design possibilities.

Digitization in Construction

The production processes in construction and architecture, in contrast to other economic sectors, have hardly changed in the past decades. While the productivity of the entire economy in the German-speaking region has recorded an increase of around 11% within the last 10 years, the construction sector has not even achieved half that amount in the same period. The reasons for this do not lie in outdated planning processes; these are usually highly developed and carried out in a contemporary manner using digital methods. Deficits or potentials, on the other hand, lie in the transfer of digital data, especially into large-format physical objects, which must meet the technical requirements. A particular challenge in this respect is posed by the cement material most frequently used in construction and architecture, which is also associated with high CO2 emissions. Through the use of new digital production technologies, the previously obligatory, time-consuming and cost-intensive formwork can be dispensed with.

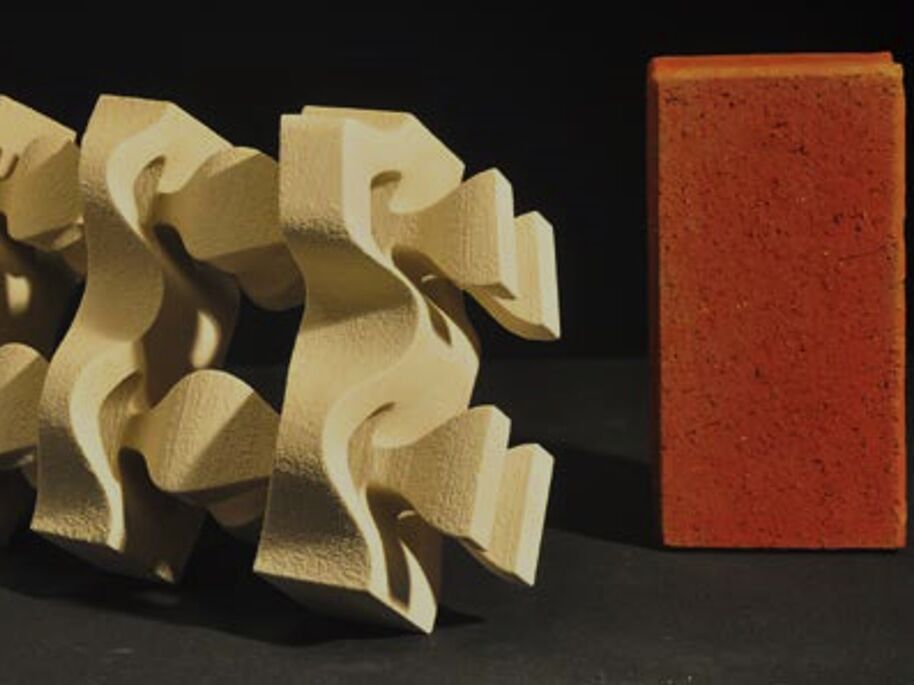

By integrating an additive manufacturing process, it would be possible not only to accelerate the construction process, but also to use the associated geometric freedom for design and material savings. In this way, large-format components could be adapted to specific requirements largely without additional costs.

Building | Concrete 4.0?

The aim of the project is to realize a digital process chain by integrating an additive manufacturing technology for the production of large-format objects with a focus on application in construction and architecture. The project focuses on the automated production of high-resolution objects from inorganic and organic materials. In the process, large-format and ready-to-use components are to be produced using low-cost powder materials, such as cement material, in an additive process. For this purpose, new materials have to be developed and the existing processes have to be adapted accordingly. In addition, new strategies for quality control are required, as these have a key function in the market launch. This, too, is to be scientifically processed within the framework of the project and also used in teaching.

Project partner: Voxeljet AG, Friedberg (Bavaria)