The project was carried out by the Department of Building Materials Technology as a research center of the Research Association of the Aerated Concrete Industry with the aim of reducing the content of calcium sulfate in aerated concrete through a better understanding of hydrothermal hardening and thus improving recyclability. Calcium sulfate can be eluted from aerated concrete and impairs, for example, the recycling of aerated concrete quarry as a substitute building material, since the limit values of sulfate in the eluate are exceeded according to current regulations. However, the addition of calcium sulfate in the production of aerated concrete is indispensable according to the current state of the art in order to guarantee the quality of the building material, especially with regard to the mechanical properties such as compressive strength and drying shrinkage.

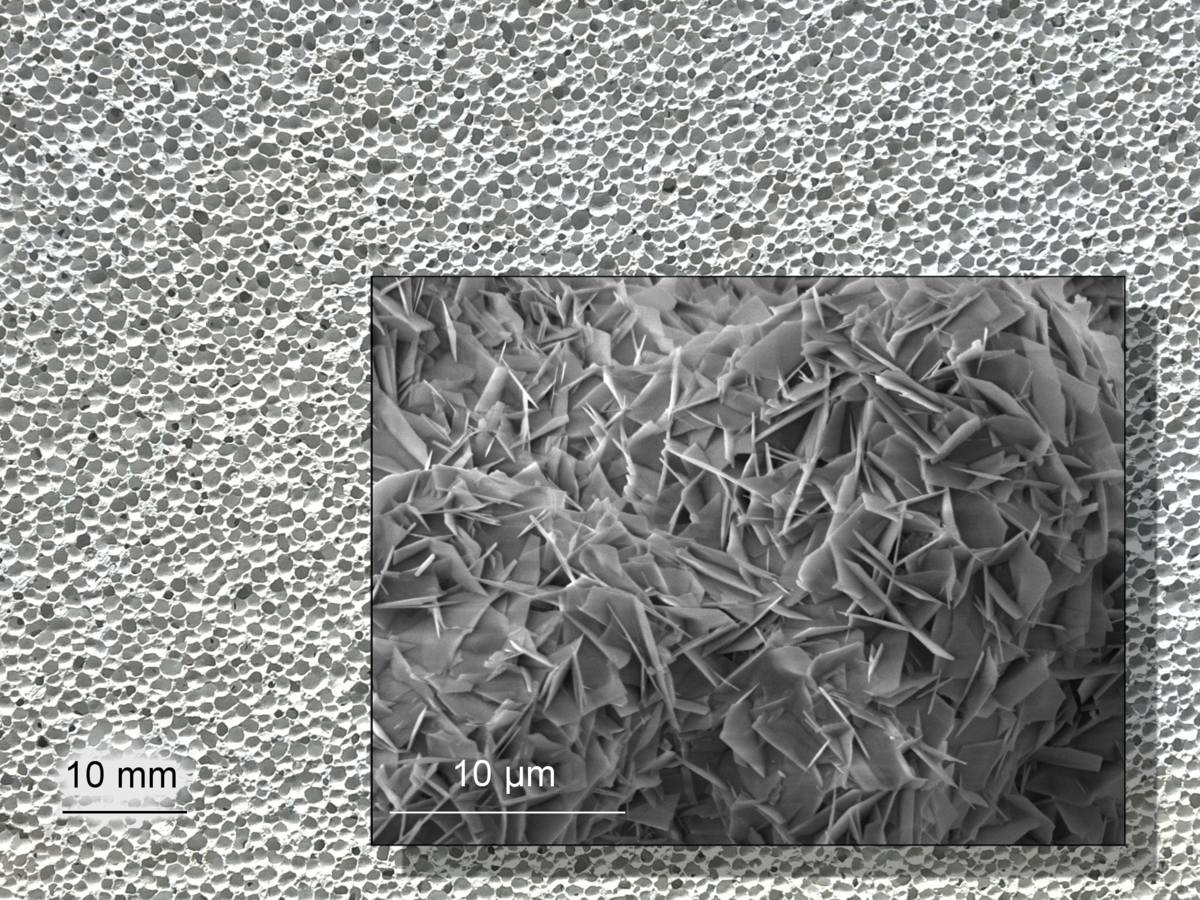

Laboratory experiments were carried out in direct cooperation with industrial partners and using the raw materials and formulations used in the factories. Among other things, test specimens were produced and examined chemically and physically in order to quantify the effect of the sulfate addition by systematically varying the raw mixtures. In addition, an in situ measuring station was set up on the basis of a modern X-ray diffractometer in order to continuously record the phase composition during the hydrothermal hardening process, which lasted several hours. The reaction processes could thus be traced and quantified. The microstructure of the resulting tobermorite phase was investigated using scanning electron microscopy. In combination, the investigations revealed the influence of the sulfate-containing phase hydroyxlellestadite, which is formed and decomposes again during hydrothermal hardening.

The result is a theoretical model of the influence of sulfate, which enables a deeper understanding of the production process in terms of process optimization, energy savings and the associated economic benefits. The investigations thus serve as a resource-saving further development of the production of aerated concrete blocks with a view to the sustainability of aerated concrete masonry.

![[Translate to English:] Footer Autoklav-XRD](/storages/hs-wismar/HSW_zentral/Forschung/Forschungsdatenbank/Projekte/2023/Autoklav-XRD/Footer_Autoklav-XRD.jpg)