Numerous processes in industry generate large amounts of waste heat at different temperature levels, which are often released unused into the environment. In the R&D cooperation project funded by the TBI M-V, Wismar University of Applied Sciences is developing a novel, energy-efficient concrete-based multi-zone heat storage system (MZWS) together with the industrial partner Betonwerk Ribnitz GmbH, which is intended to enable the short- to medium-term storage of waste heat at a temperature level of up to approx. 400°C.

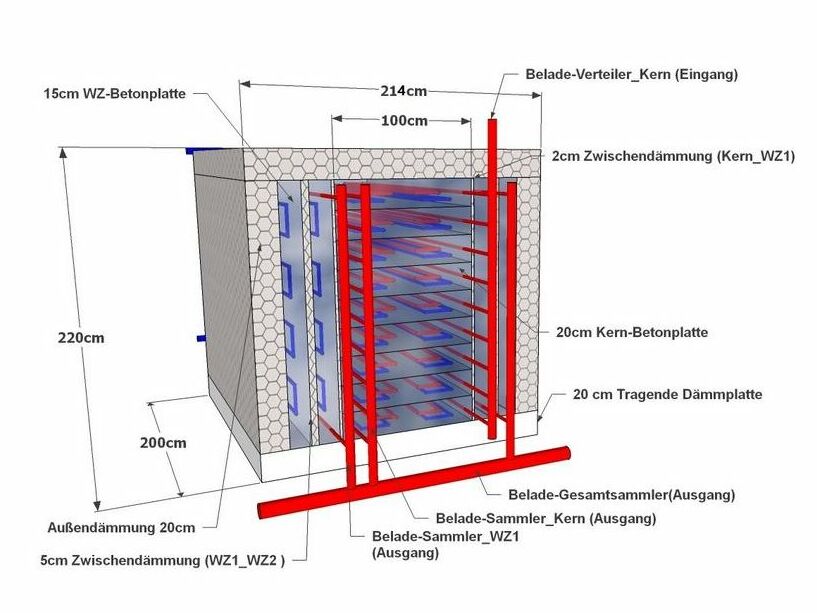

Concept of the multi-zone heat accumulator:

The heat storage zones arranged around the storage core are separated from each other by intermediate insulation. This stratification system leads to a delayed heat transport from the inside to the outside, and thus different temperatures with a falling gradient from the inside to the outside occur in the different heat storage zones depending on the amount of heat supplied (e.g. 330 °C in the core, 120 °C in heat storage zone 1 and 25 °C in heat storage zone 2). In this case, the temperature gradient between the outer heat storage zone and the surroundings is at a significantly lower level than with a single-zone heat storage system (for this example 5 K instead of 310 K). This means that the transmission of heat losses to the surroundings can be greatly reduced due to the smaller temperature gradient. The heat energy available in the different storage zones can be used as needed at different temperature levels for different applications. The residual heat of the core change return can also be used to load the cooler heat storage zone, so that the energy-efficient utilization of the heat source is maintained. A special concrete formulation was developed for this task, which ensures good heat resistance, high thermal conductivity and a large heat storage capacity. A MZWS was designed on a laboratory scale, which can be used to investigate a wide variety of dynamic loading and unloading scenarios and to balance the respective heat flows. In 2018, a pilot heat storage system was created at the Ribnitz concrete plant to demonstrate the advantages in terms of energy efficiency and variable heat utilization in a practical test.

Team: Environment and Process Engineering WG

Staff: Dr.-Ing. Muhamad Ayas Harfosh