Unlike in the automotive industry, where the use of robots has led to considerable increases in productivity in recent decades, the construction industry is still far from comprehensive automation. Although the first approaches to the automated production of standard prefabricated parts also exist in concrete construction, these hardly fulfill the desire for individually shaped building structures, which are particularly prevalent in residential construction. The high quantities of automobile production are not achieved here, which is why the automation of processes in the production of free-form concrete components cannot be economically justified so far. In order to achieve this goal, new and innovative processes are needed with which small series and one-offs can also be produced and marketed competitively.

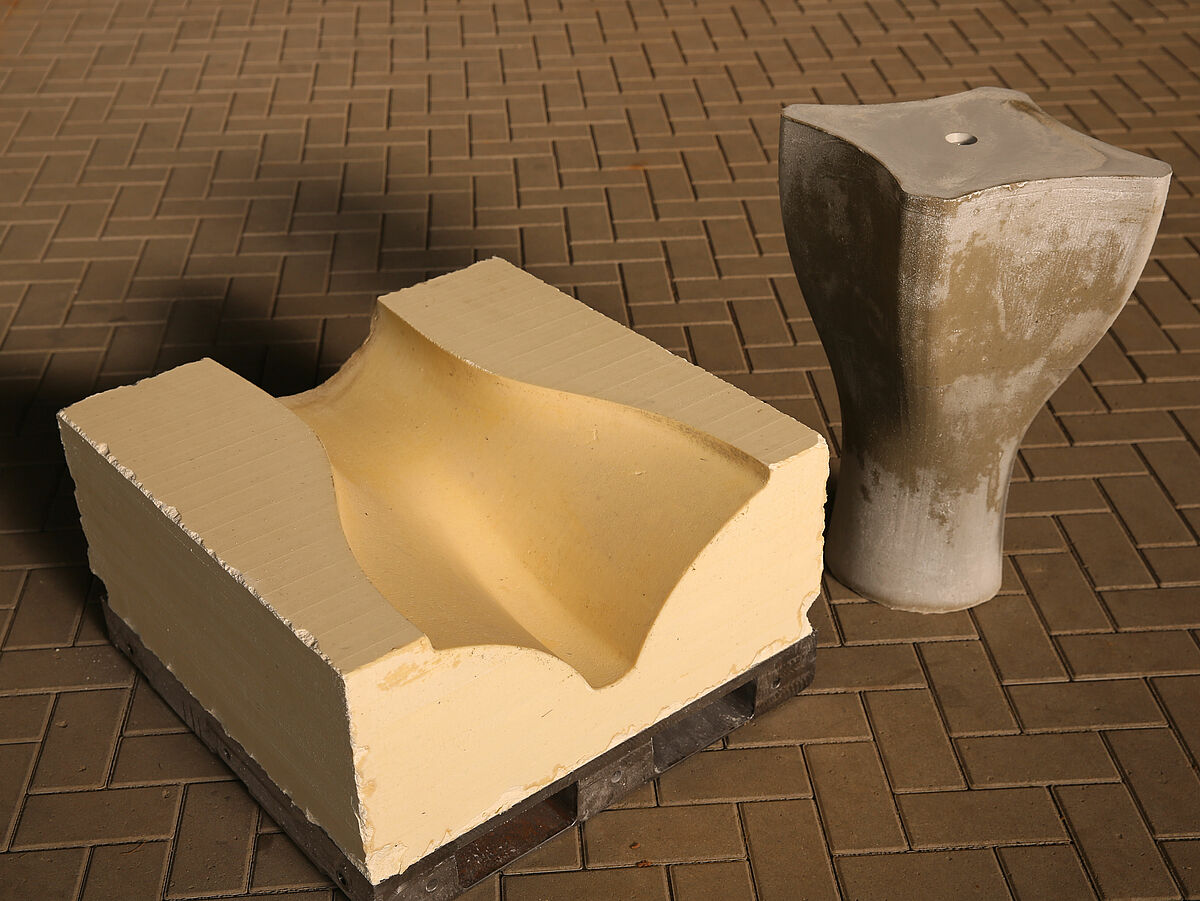

This is where the Ph.D. project comes in. The goal is a fully automated and waste-free production process for free-formed concrete components. For this purpose, industrial wax is pressed into blocks and then shaped into free-formed formwork modules by machine milling. These, in turn, can be assembled similar to the Lego principle to form a complete formwork of any size and filled with concrete. After the concrete has hardened, the wax formwork modules and the wax shavings produced during milling are 100 percent recycled by being fed back into the production process.

All in all, the research project points the way to a production process with which individual and mass-produced unique concrete components can be manufactured cost-effectively and used in the construction industry.

PhD project by Dr.-Ing. Franz Wirth, Supervisor:

- Univ.-Prof. Dr.-Ing. Harald Kloft, Institute for Structural Design, TU Braunschweig

- Prof. Dr.-Ing. Asko Fromm, Faculty of Design, Wismar University of Applied Sciences

Cooperation partner:

- B+S Engineering GmbH, Rheine