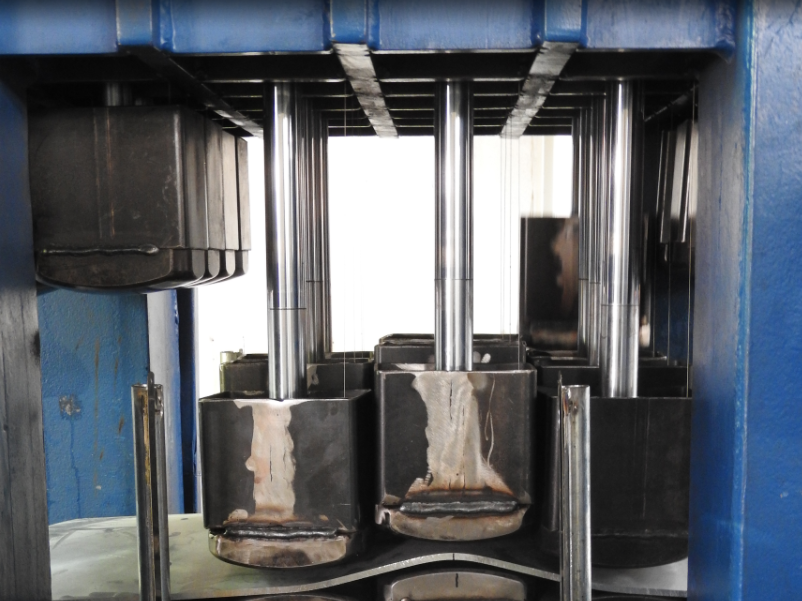

The required high quantities paired with high repeatability virtually rule out the manufacture of such products with conventional manual, experience-based methods. Therefore, the implementation of new concepts for forming is necessary, since the high quantities and adequate quality required in the future can only be achieved through a higher degree of automation. The primary objective of this sub-project is the modification of a multi-stamp press test facility into a test facility that allows series production testing. Modern control systems from PLCs to industrial PCs on the one hand and comparatively inexpensive intelligent sensors for the contactless measurement of temperature and distance on the other hand enable the development of innovative process automation for this plant.

Project Partners: Formstaal GmbH & Co. KG, Stralsund University of Applied Sciences (Prof. P. Meier)